Main Features

1) Energy-saving design, high performance and efficiency, saving electricity in large degree.

2) Remote intelligent management system, automatic high precision digital controller is easy to operate with high efficiency.

3) Imported European compressor, low noise and high reliability, world renowned brand refrigeration accessories guaranteeing longer service life.

4) Adjustable indoor temperature, according to cooled products to adjust the most suitable temperature.

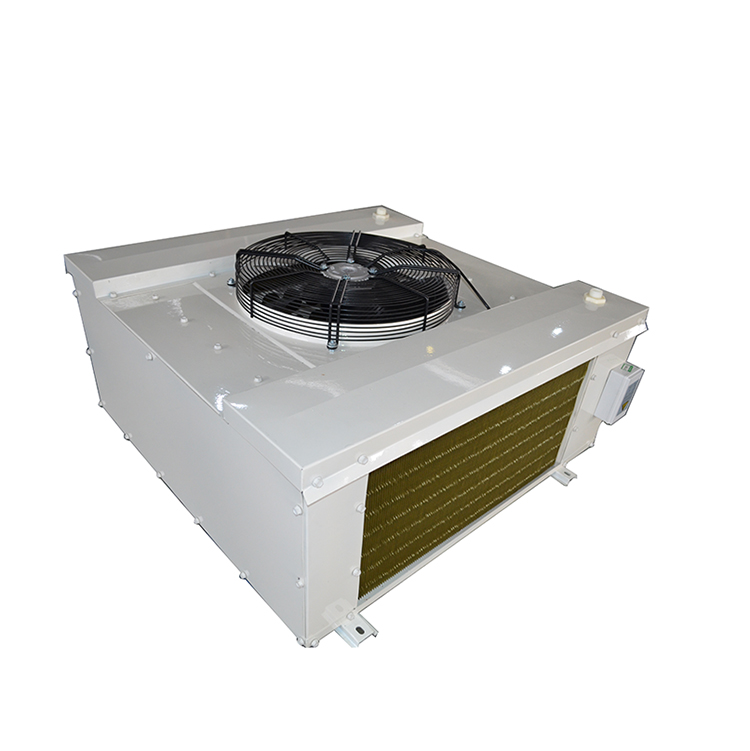

1. Exterior-protected structure

The reference value of the suspension load is designed as 70~80kg/m2 when adopting seamless pipe to make aluminum alloy pipe row while 40~50kg/m2 when adopting aluminum alloy as pipe row. If cold air blower, only partial suspension load need to take into consideration.

2. Refrigerant charge capacity

Aluminum alloy pipe row cold room needs about 2~5 times refrigerant more than cold air blower cold room.

Capacity of fluorine in cold air blower is small because the small inner volume and floor area.

Diameter of aluminum alloy pipe row differs from 22~38 mm. Larger diameter, more fluorine capacity.

3. Initial investment

Compare from the evaporator selection, initial investment of aluminum alloy pipe row is more than cold air blower about 15%~25%. Price difference is more and more obvious when whole system is large. Besides, construction period of aluminum alloy pipe row is about 3~4 times more than cold air blower, so labor cost is more.

4. Defrosting way

Cold room with cold air blower defrosting ways: natural defrosting,water flushing frost, electrochemical frost, hot fluorine(ammonia) defrosting. Cold air blower is easy to realize natural defrosting, defrosted water flows to outside from water tray and pipe.

Cold room with aluminum pipe row defrosting way: usually hot fluorine defrosting. But defrosted water will drop from roof of factory so products need to move or covered by plastic film, not as convenient and flexible as cold air blower.